Showcasing Industrial Strength at the Romania Expo

MEP TEKNİK Continues to Lead the Industry at the Romania Fair

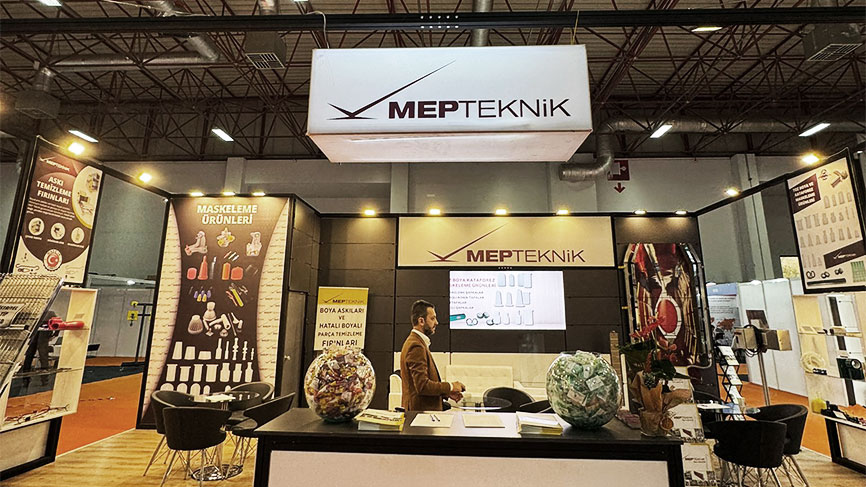

Offering high-tech solutions in the field of industrial painting systems, MEP TEKNİK continues to showcase its products at the international industry fair held in Romania. This event marks a significant step in the company’s strategy to expand within the European market and highlights MEP TEKNİK’s sectoral strength and solution-oriented approach. With its broad product range, energy-efficient systems, and expert technical staff, MEP TEKNİK has become one of the most notable exhibitors at the fair.

A Gateway to Europe: The Strategic Importance of the Fair

The Romania fair not only strengthens MEP TEKNİK’s relationships with existing customers but also paves the way for new business partnerships. Numerous industry professionals from different countries have shown great interest in MEP TEKNİK’s products and services throughout the event. These interactions play a vital role in the company’s Eastern European growth strategy.

Featured Product: Industrial Infrared Heaters

Among the most attention-grabbing solutions at the fair were the Infrared Heating and Drying Systems. These systems stand out for their energy-saving performance, fast drying capability, and environmentally friendly design—perfectly reflecting MEP TEKNİK’s innovative approach to production technologies.

-

High Efficiency and Energy Savings

MEP TEKNİK’s infrared heaters provide significantly faster heat transfer compared to traditional heating methods. This enables quicker results and considerable reductions in operational costs. -

Modular and Flexible Structure

Designed to suit each production line, these systems can be easily integrated into existing operations thanks to their modular design—minimizing downtime and reducing installation time. -

Contactless Heating Technology

Infrared heaters deliver heat without direct contact with the material surface, making them ideal for sensitive materials that require gentle handling. -

Wide Application Range

Used across various industries—wood, plastic, metal, textile, and glass—infrared systems offer high performance in drying, paint curing, and preheating. -

Eco-Friendly, Low Carbon Footprint

Thanks to direct energy usage and localized heating, infrared systems significantly reduce environmental impact, fully aligning with MEP TEKNİK’s sustainable manufacturing goals.

These systems were demonstrated live at the fair and attracted strong interest, particularly from professionals in the automotive, furniture, and metal processing industries. Click here to view the product page for technical specifications and application examples.

Hanger Cleaning Furnaces and Additional Systems

Another standout solution presented by MEP TEKNİK at the fair was the Hanger Cleaning Furnace, which increases the reusability of hangers in coating lines—offering both economic and environmental advantages. These furnaces support green manufacturing by reducing energy consumption, cutting carbon emissions, and offering automation options.

Hanger Cleaning Furnaces are especially useful in electrostatic powder coating lines where hangers are reused multiple times. They significantly reduce operational costs and contribute to environmental sustainability.

-

Production and Service in One

MEP TEKNİK not only manufactures and sells hanger cleaning furnaces, but also offers contract-based hanger cleaning services. This gives companies looking for short-term or non-investment solutions access to professional support. -

High Heat, Deep Cleaning

Operating at 400–450°C, the furnaces effectively remove paint residues from hangers, significantly extending their usable life. -

Automation-Enabled Efficiency

Optional PLC automation improves process traceability and reduces operator errors, ensuring a safe and controlled cleaning process. -

Tailored to Different Hanger Types

The furnaces can be customized for hangers of various shapes and sizes, providing efficient and compatible solutions for many production lines. -

Eco-Conscious Design

The cleaning process uses only high heat without chemicals, minimizing environmental impact and reducing carbon emissions.

Live demos at the fair attracted particular interest from professionals in the metal painting, automotive, and white goods sectors. Both investors and production engineers were keen to explore the advantages these systems offer.

For detailed information and technical documentation, click here to visit the product page.

Other Product Groups on Display:

-

Industrial Infrared Heaters

-

Drying Ovens

-

PVC Masking Elements

-

Electrostatic Powder Coating Booths

-

Wet Paint Booth Systems

-

Surface Cleaning Systems

-

Quality Control Devices

Each product can be reviewed in detail with technical specifications on mepteknik.com.

The Power of Expert Staff and Face-to-Face Presentations

Experienced engineers at the MEP TEKNİK booth conducted one-on-one technical presentations for visitors. Demonstrations using live demo units allowed participants to see exactly how the systems work in real-world conditions. The Coating Thickness Measurement Device stood out with its user-friendly interface and fast measurement capabilities.

New Markets, New Goals

For MEP TEKNİK, this fair is not just a marketing event—it’s also an opportunity for market research and strategic partnerships. Meetings with participants from countries such as Bulgaria, Poland, Serbia, Hungary, and the Czech Republic signal the upcoming establishment of new dealerships and technical service points.

Digital Support: Access Through the Website

Part of the interest at the fair was also driven by digital engagement through www.mepteknik.com. Visitors can continue interacting with the company post-event through access to product catalogs, user manuals, promotional videos, and online consulting services—aligning with MEP TEKNİK’s vision of digital transformation and enhanced customer experience.

Gallery: Highlights from the Romania Fair

A Participation That Shapes the Future

With its participation in the Romania fair, MEP TEKNİK once again reinforces its leadership in the industry. Its domestic manufacturing strength, engineering solutions that meet international standards, and customer-centric approach make the company a provider not only for today's needs but also for tomorrow’s demands.

Following the fair, MEP TEKNİK aims to further expand its service and distribution network in Europe, deliver its products to new markets, and help shape the future of the industry together.

For more information, visit: www.mepteknik.com